If you haven’t already, take a look at the Design Process behind Play It By Ear.

Play It By Ear went through a rigorous design process, involving much prototyping, research, and testing (which you can read about here). When it came to fabricating & installing the artwork, almost every element had to be carefully considered, hand-crafted, and planned specifically for this piece.

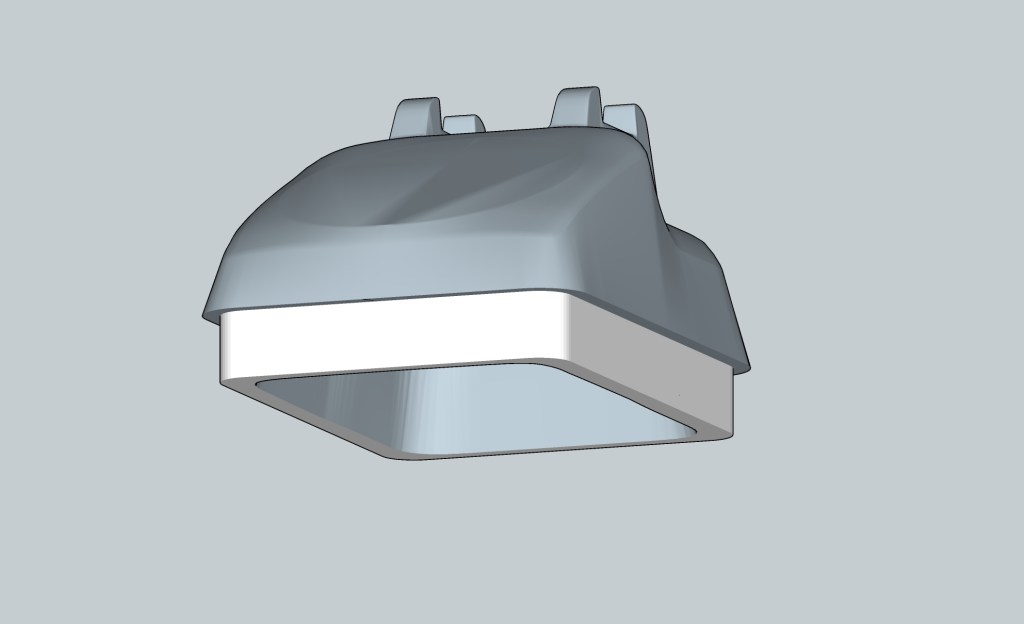

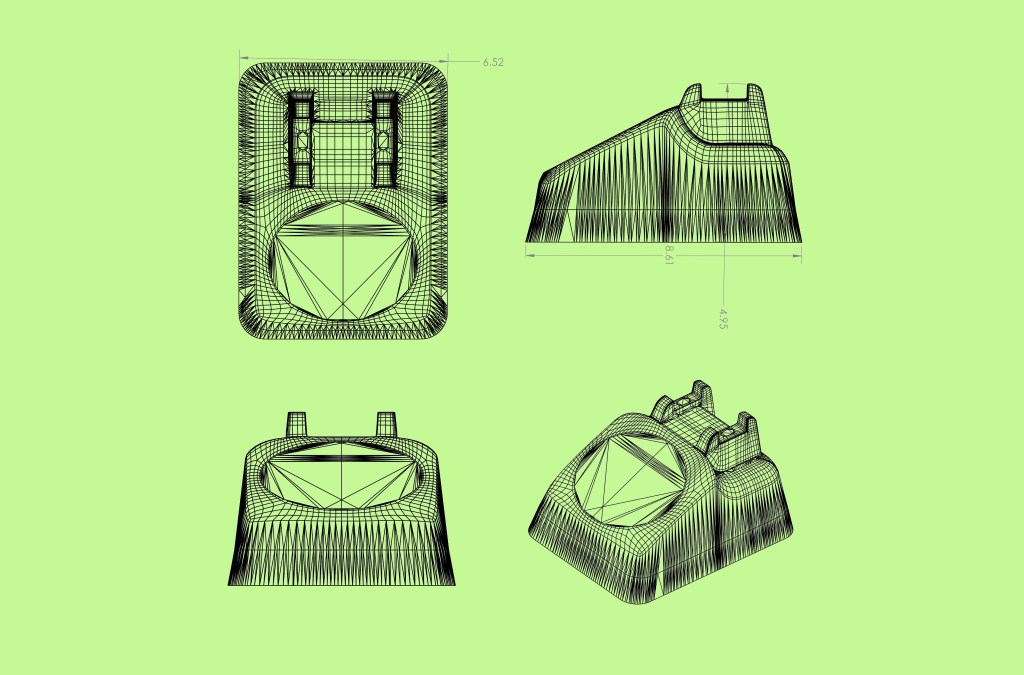

In terms of the aluminum telephone cradles, we worked with Hayden Pattullo (Studio North) to create 3D design files, which were then sent to a pattern maker at West of the Fifth, who made a physical pattern. This pattern was sent to Melting Pot Foundry where they poured the cradles in liquid aluminum.

The next step was machining these “blank” aluminum cradles to fit flush on the HSS tube telephone pillars, and cutting circular windows into the faces of the phones.

Luckily, in another life, Wayne Garrett (co-artist) worked as a Red Seal Machinist. He was able to do a majority of the more finicky metal work himself, working in a fabrication shop near Cochrane called Coyote Works, which typically creates special FX for the film and television industry.

The HSS tubing was adapted, including a long smooth cut in the front surface where light will emanate, and many holes and bolts to accomodate hardwate.

It’s impossible to see all the micro-details that went into this laborious phase of fabrication – cutting, welding, machining, sanding, grinding, and so much more.

Once this process was complete, the phones went to the painters to be filled, resanded, primed, and painted.

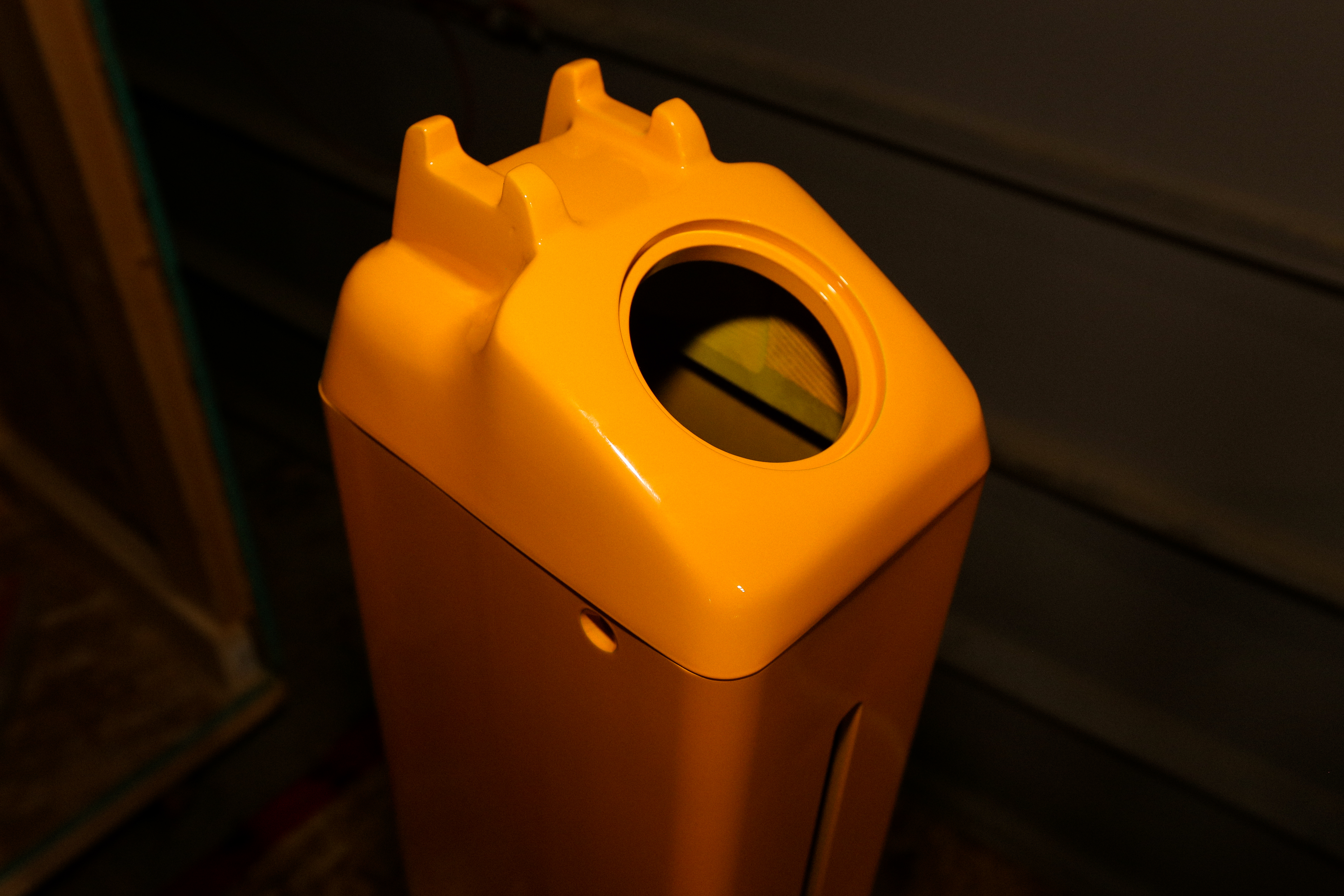

We asked ACR Paint & Autobody to make the phones look like candy. They asked a few questions about our priorities and how much filling they should do (the cradles were slightly pitted from the casting and fabrication process), before getting to work.

The painted phones look so glossy and perfect… definitely candy-coated! Ideally they will hold up to weather and minor vandalism before they require repair.

The internal electronics were fabricated incrementally in our home studio. Again, we accomplished as much of this process independently as possible.

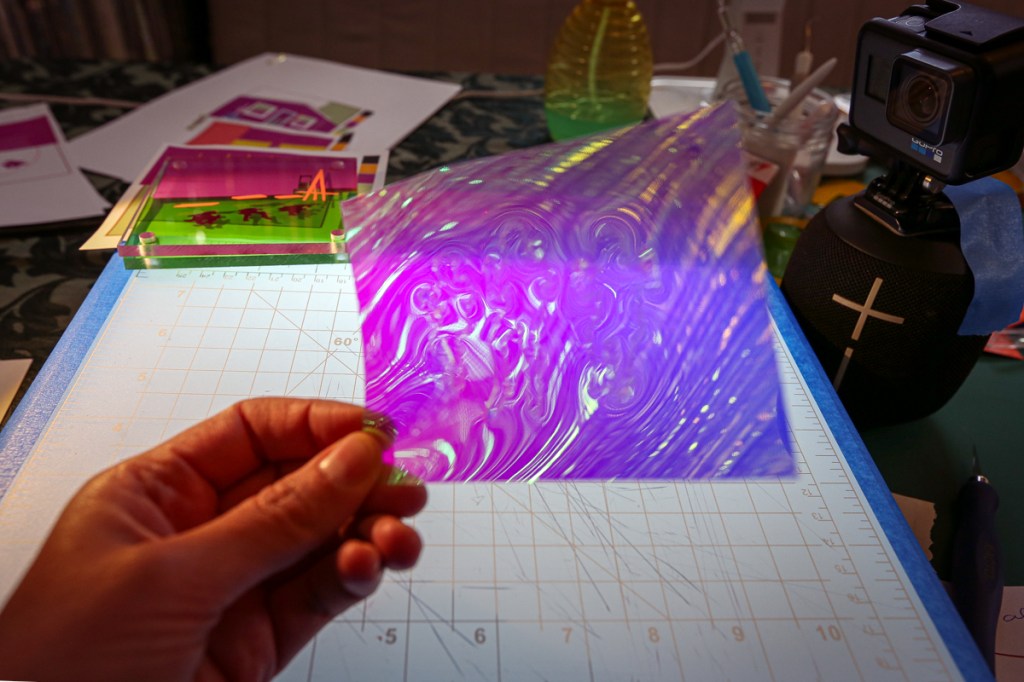

Similarly, the telephone windows were fabricated in our home studio. We’ll explain the “home phone” imagery in these circular windows in the following blog post.

The final assembly was done onsite in the park – after the painters had finished their work.

The underfoot painting required a brief closure of Butler Memorial Park to allow the paint to properly cure before being exposed to pedestrian traffic. Our concrete painters, GLVT, fenced, cleaned, and acid-etched the concrete, preparing it for the Tuffcoat paint.

We chalked the swirling “landlines” onto the concrete, and GLVT followed us with their bizarre and amazing tape machine.

Once the tape lines were laid, GLVT primed and began painting our pattern onto the concrete.

The painting process took only a few days, but curing added an additional 5-7 days. During this time, we finished installing the telephone pillars onsite. Suddenly, Play It By Ear was finished and ready for participation from people in West Jasper Place!